The figure above shows the extent of the input energy being injected into the system. The heat pumps composed of the chiller and the freezer harvest energy from the environment. This acquired energy is FREE and is made to do work in the drying process. Notice that it is actually the arrangement of the components makes the system attractive.

This dryer system integrates all the energy in the system into the drying function. We have energy from the fuel, energy harvested through heat pumps, and energy directly gathered from the environment.

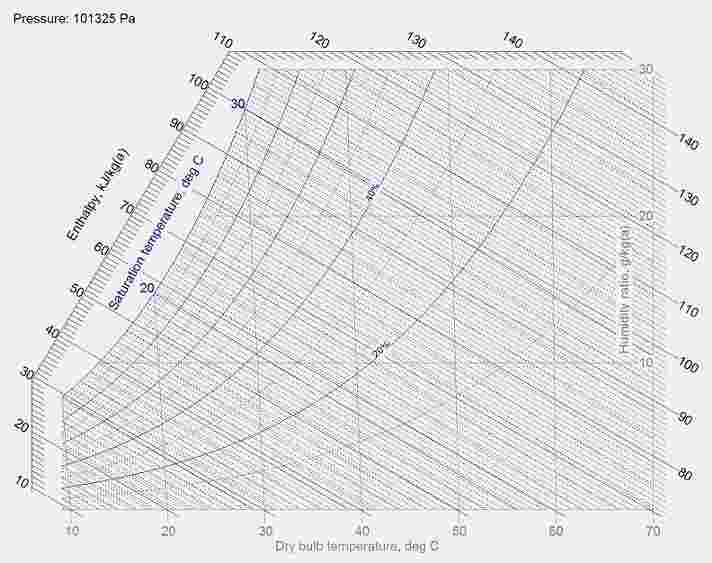

The chart above shows the action of heat pumps. In this example, you will notice the energy input gathering energy from the items to be chilled, or frozen, and both combine as heat. This resultant energy is made available for the drying function. Look at air-conditioning equipment all around - all this heat is simply discharged into the environment.

The physics of absorption chillers is really very simple. It takes advantage of the fact that water boils at a lower temperature when exposed to pressure that is lower than atmospheric. The water that evaporates leaves behind a cool surface.

1.0.1 Rule for Operating Internal Combustion Engines. The operational philosophy is that internal combustion engines will be operated only at their best efficiency. All waste heat that can be recovered is so recovered.

1.0.2 Hybrid Mechanical and Electrical Design. This leads to the issue of excess shaft power when the mechanical and/or electrical load conditions are low. The solution is to provide enough DC power generation capability to charge batteries and a 3-phase variable frequency inverter that drives a 3-phase motor to transmit its power to the main drive shaft that is described below. This is similar to the engineering design philosophy that I have incorporated into my hybrid-electric vehicle. You could check this out at "http://hybrid.thcal.com", or visit "http://www.thcalasanz.com/thcalasanz/index.html" for the appropriate links.

1.0.3 Integrate Energy Efficiency with Renewable Energy. The location that integrates "energy efficiency systems" and "renewable energy resources" will provide battery charging banks. Electric vehicles will charge their batteries here. Hybrid-electric vehicles will either charge their batteries, or deliver batteries that they have charged during the day.

1.0.4 Feedback to the Grid. It is at this location that feedback to the grid will be undertaken, if it is available. It is also here that charging batteries from the grid would be undertaken.

1.1 Engine and Drives

- With available conversion kits in the market, convert two, 2-liter (or 1.8-liter) gasoline engines to Liquified Petroleum Gas (LPG), or Liquified Natural Gas (LNG), or Compressed Natural Gas (CNG)

- Install them as stationary prime-movers with drive-shafts driving one main drive-shaft

- Install the appropriate capacity of automotive generators at the main drive-shaft

- Install the appropriate capacity of freezer compressors also on this main drive-shaft

1.2 Process Items

- Connect appropriate pipes and heat exchangers to transfer the heat of the jacket water to the boiler feed-water

- Install a waste heat recovery boiler using the exhaust gases as the source of heat to generate steam

1.3 Heating, Chilling, and Drying

- Procure and install the appropriate capacity of Lithium-Bromide absorption Chillers. I understand that the Japanese have developed this technology to the point that they are rather efficient and cost-effective today. I do not have all the brands names, but searching for Sanyo, Mitsubishi, Hitachi, Kawasaki, and York absorption chillers should be a good start.

- Bring the steam to the absorption chiller to generate chilled water at 6 degrees Celsius

- Convey the gases of combustion to a drying chamber for produce or for the production of high grade salt

1.4 By-Products

- Collect the essence from the produce being dried

- Build a water evaporator at the end of the exhaust gas path

- Condense the water and process it for drinking

1.5 Resorts and Hotels

- Resorts and hotels, which are located near this facility can source its electricity needs from here. It can also source its hot water for cooking and for its laundry from here. In addition, it can be provided chilled water for its air-conditioning needs.

1.6 CLEAN WATER GENERATION FROM AIR

- The cogeneration facility is able to produce clean potable water by bringing air in contact with cooled surfaces, whose temperatures are well below the dew-point temperature of the air.

- Let us review the principles of psychrometry. We know that ambient air carries moisture. The extent of the moisture content is dependent upon the humidity of that air. In common terms, we have expressed this humidity in "percent relative humidity". In any case, we could locate the "dry-bulb" and the "wet-bulb" temperatures of the air on a psychrometric chart to determine the dew point temperature. Knowing this "dew-point" value, we design cooling coils that will operate well below it.

- The condensation of water outside a cold glass of drink is the same action as the one we are describing. The condensation is more when the glass is colder, and it will even be more during and after it rains, because the moisture in the air has increased.

- The engineering of it consists in our utilizing the "new energy" we have gathered from energy efficiency projects and from renewable energy resources to bring the temperatures of the surfaces of the cooling coils to achieve our purpose. The even more challenging issue is achieving this condensation without the use of power from the grid, if this happens to be an "off-grid", or "decentralized energy system".

- Creativity and ingenuity manifest themselves, when one uses a battery, designs an inverter from scratch, drives an AC motor, to drive an automotive compressor. This makeshift way of producing cooling coil surfaces, whose temperature is lower than the "dew-point" of ambient air is found in a study conducted by Mr. Paul M. Cabacungan, et al., of the Ateneo de Manila University. The work may be accessed through the ECCE Department of Ateneo.